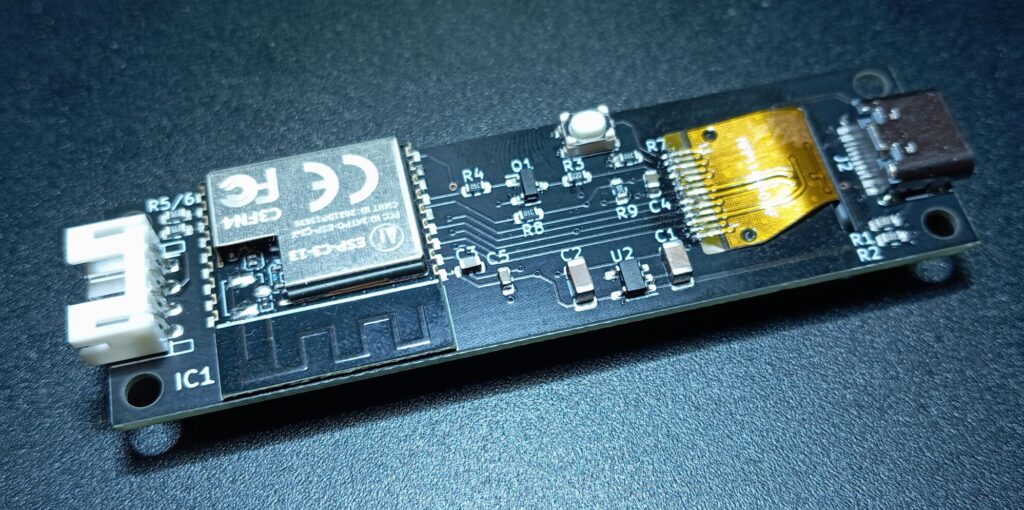

After the boards had been lying around unassembled for a year, it was time to solder the components and run a simple program as a test.

The components on the underside could be quickly soldered with a hotplate. Only the flat flex cable and the 2 mm plug for connecting the LEDs had to be soldered by hand.

All that remains is to solder the small 5-way joystick to the top of the board and we’re done. The board can be fitted with a 0.96 inch IPS display with 80×160 pixels or a 1.14 inch display with 135×240 pixels. An ST7789 is used as the controller. For the first test, however, we will not control the display.

#include "FastLED.h"

#define NUM_LEDS 50 // Enter the total number of LEDs on the strip

#define PIN 21 // The pin connected to Din to control the LEDs

CRGB leds[NUM_LEDS];

void setup() {

FastLED.addLeds<WS2812, PIN, RGB>(leds, NUM_LEDS).setCorrection(TypicalLEDStrip);

FastLED.setMaxPowerInVoltsAndMilliamps(5, 1500); // Set power limit of LED strip to 5V, 1500mA

FastLED.clear(); // Initialize all LEDs to "off"

}

void loop() {

rainbowCycle(20);

}

void rainbowCycle(int DelayDuration) {

byte *c;

uint16_t i, j;

for(j=0; j < 256; j++) {

for(i=0; i < NUM_LEDS; i++) {

c = Wheel(((i * 256 / NUM_LEDS) + j) & 255);

leds[NUM_LEDS - 1 - i].setRGB(*c, *(c+1), *(c+2));

}

FastLED.show();

delay(DelayDuration);

}

}

byte *Wheel(byte WheelPosition) {

static byte c[3];

if(WheelPosition < 85) {

c[0] = WheelPosition * 3;

c[1] = 255 - WheelPosition * 3;

c[2] = 0;

}

else if(WheelPosition < 170) {

WheelPosition -= 85;

c[0] = 255 - WheelPosition * 3;

c[1] = 0;

c[2] = WheelPosition * 3;

}

else {

WheelPosition -= 170;

c[0] = 0;

c[1] = WheelPosition * 3;

c[2] = 255 - WheelPosition * 3;

}

return c;

}

The board can be programmed and supplied with power directly via USB. The example program above uses the FastLED library to create a rainbow that runs through the LEDs.

Leave a Reply